Certified quality management system

Pump Control 22kW SPC22

£1,902.33*

Details

+49 421 277 9999

Product information "Pump Control 22kW SPC22"

Highlights

- Motor power: up to 22 kW / 400 V

- Rated current: 45 A

- Integrated frequency converter ST500

- Mains filter SFI (C2 environment)

- Motor choke

- Dry-running protection via current measurement

- Connections:

- External dry-running protection

- Motor temperature monitoring (PT100/PT1000/PTC)

- Protection concept:

- Overvoltage, undervoltage, overload protection

- Phase symmetry monitoring

- Password protection

Technical Data

- Power (motor): up to 22 kW

- Output voltage (motor): 0-400 VAC 0-50 Hz

- Maximum frequency: up to 3200 Hz

- Operating voltage: 400 VAC 50/60 Hz

- Rated current (inverter): 46.5 A

- Back-up fuse: 100 A

- Supply cable: max. 10 mm² copper

- Motor cable: max. 10 mm² copper, max. 50m long (shielded)

- Protection class: IP54, EN60529/NEMA4

- Dimensions (W/H/D): 800/1000/300 mm - The dimensions may vary depending on the version due to additional components such as filters, switches, etc.

- Weight: 50 kg

Functions |

|||||||||||

|

|

|

||||||||||

Other data |

|||||||||||

|

Housing

|

Connections (bottom)

|

||||||||||

|

Protective functions

|

Scope of delivery

|

||||||||||

Optional

- Pressure transmitter for pressure control

- GSM module for fault messages

- Project planning of the entire system

- Installation, commissioning & service

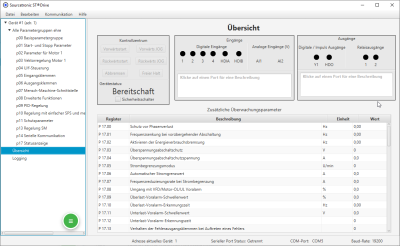

- Software: ST®DRIVE, ST®APP

- Platform Fontaine 24/7

- Cascade control

The SPC22 pump controller is the best choice for power-saving and versatile control/regulation of your pump application. Wired and tested according to standards, the SPC22 pump control offers the quality you have come to expect from Sourcetronic. The integrated ST500 frequency converter combines many electronic protective functions and state-of-the-art digital technology. Extensive functions of the inverter are read and controlled via a removable control panel with two-line LED display, multifunctional rotary wheel and 7 keys. The parameters of the frequency inverter can be conveniently stored in the display for easy transfer to other controllers.

This pump control is the professional solution for operating a pump in industrial and craft applications as well as in municipal sewage stations and pumping stations. The SPC22 has a manual and an automatic mode, which can be selected via a toggle switch in the control cabinet door. In manual mode, the pump runs at the frequency set with the potentiometer in the control cabinet door. In automatic mode, the integrated PID controller controls the speed of the pump. The control can be used in dependence of all process values (e.g. pressure control, level control) whose actual state can be transmitted to the inverter by means of a suitable transducer (0-10 V or 4-20 mA). The setpoint to which the pump control regulates the pump with the aid of the actual value (e.g. actual pressure) is set via the control panel of the frequency inverter. Optionally, the frequency inverter can be set so that the PID setpoint is specified with the potentiometer.

Accessoires

- Frequency Inverter Quick Service

- Installation, commissioning, trial operation

- Instruction of the operating personnel

- Identification of error causes

- Reduction of subsequent and repeat faults

- Maintenance, servicing and retrofitting of systems

- Lifecycle management of drive technology

- Around-the-clock service": 24/7 monitoring service of plants

- Installation & Commissioning

- Configuration and parameterisation

- Switch cabinet construction

- Electrification of entire construction sites

- Frequency converter exchange

- Standard-compliant documentation

- Instruction of the operating personnel

- Consulting and design drive technology

- Project planning Electrical engineering

- E-construction ePlan P8

- Programming/visualisation (PLC/HMI/JAVA)

- Monitoring, control and regulation systems

- Sensor consulting

- Processing of tenders with focus on drive technology, automation, pump controls

- Determination of energy saving potentials

- Planning, construction, delivery and installation of control systems

- Devices: ST300 (Beta) / ST500 / ST600 series

- Clear parameter structure

- Easy changing of parameters

- Parameters can be saved on the PC and printed out via a printer

- Saved parameter files can be reloaded as a backup

- Communication via USB-RS485 adapter cable

- Control of a AC-Drive with an Android App via bluetooth

- Devices: ST9000 / ST500 series

- Plug and Play

- Control

- Operating system: Android

- Language: English

- Reliable equipment monitoring

- Remote management of equipment

- Certified ISO 27001 data processing

- Two-factor authentication

- Data volume: 500MB included

- Billing: annually

- Term: monthly cancellable

- Quick Start VPN Router

- Scalable and highly available

- Certificate-based authentication X.509

- Access to devices behind the router

- Billing: annually

- Term: can be cancelled annually

- Measuring range: 0... 10 bar

- Process connection: G 1/4 A DIN EN ISO 1179-2

- Output signal: 4... 20 mA, 2-wire

- Power supply: 8... 30 V DC

- Accuracy: 0.5% BFSL

- Print type: relative

- Electrical connection: Angled plug DIN EN 175301-803 A

- Assignable electrical output: UB=1, 0V=2

- Measuring range: 0... 16 bar

- Process connection: G 1/4 A DIN EN ISO 1179-2

- Output signal: 4... 20 mA, 2-wire

- Power supply: 8... 30 V DC

- Accuracy: 0.5% BFSL

- Print type: relative

- Electrical connection: Angled plug DIN EN 175301-803 A

- Assignable electrical output: UB=1, 0V=2