Certified quality management system

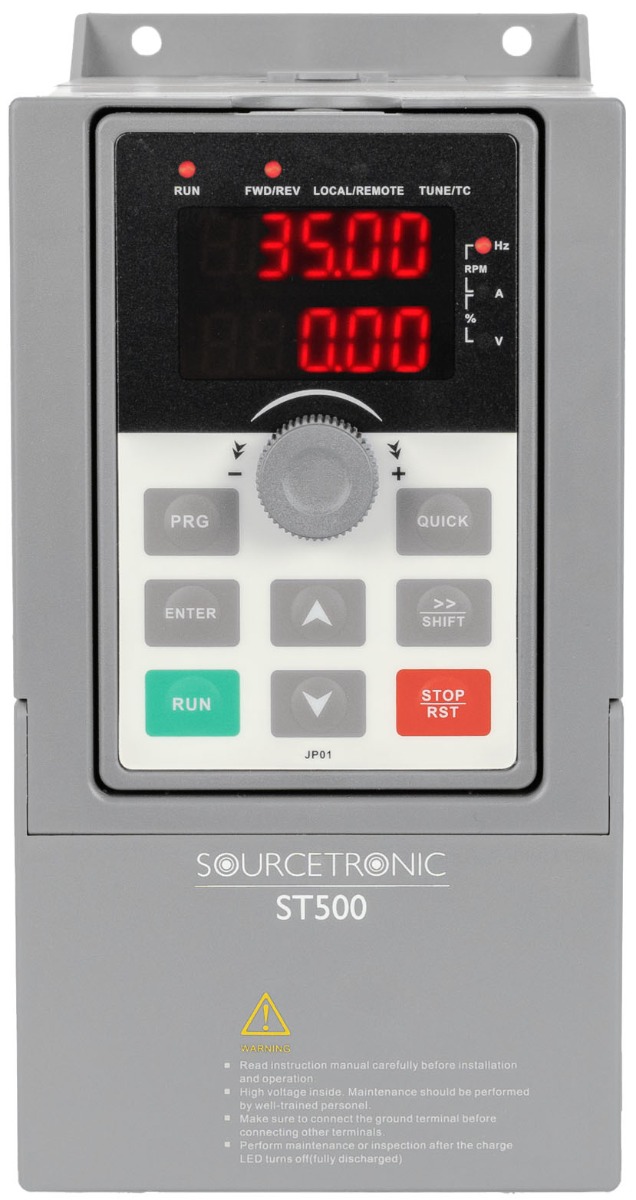

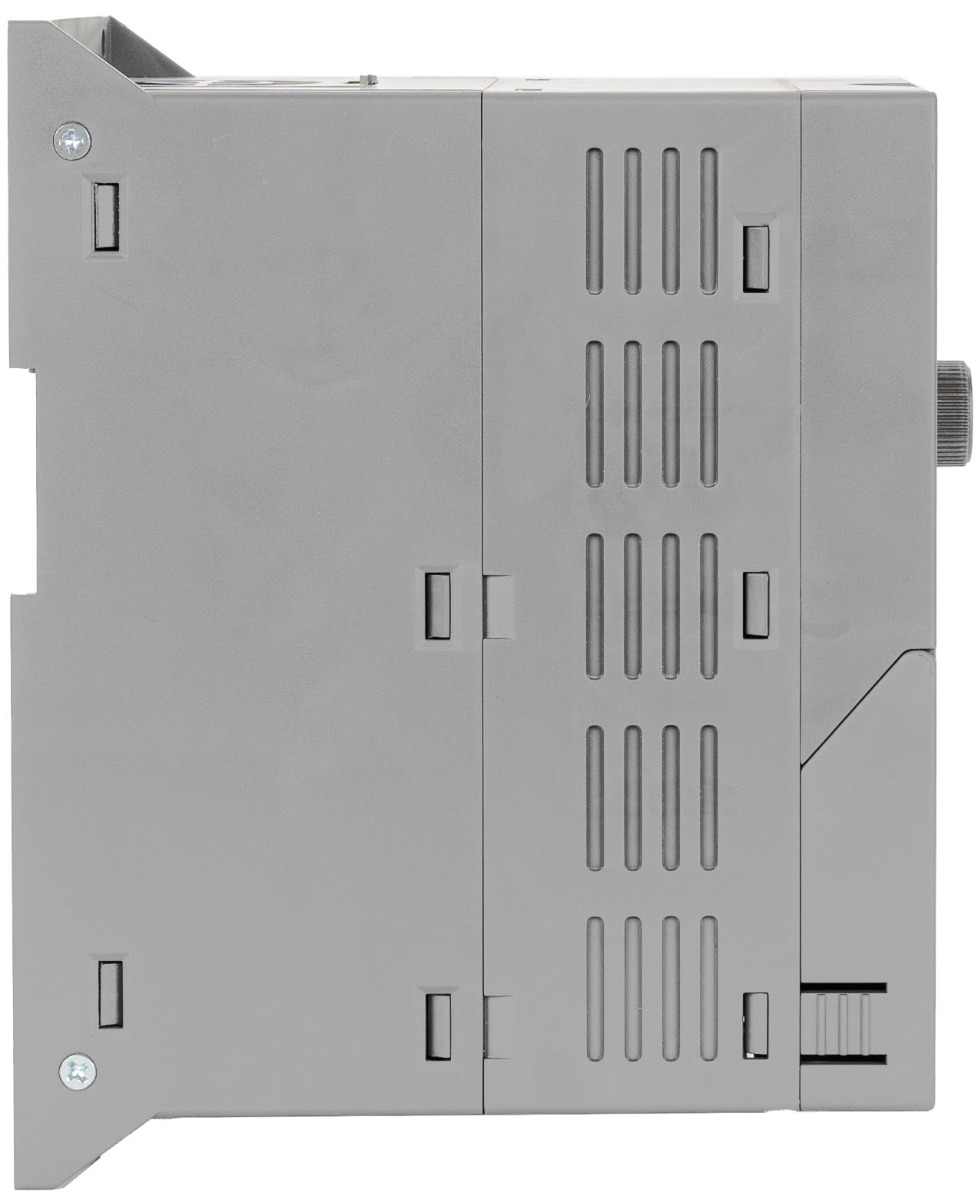

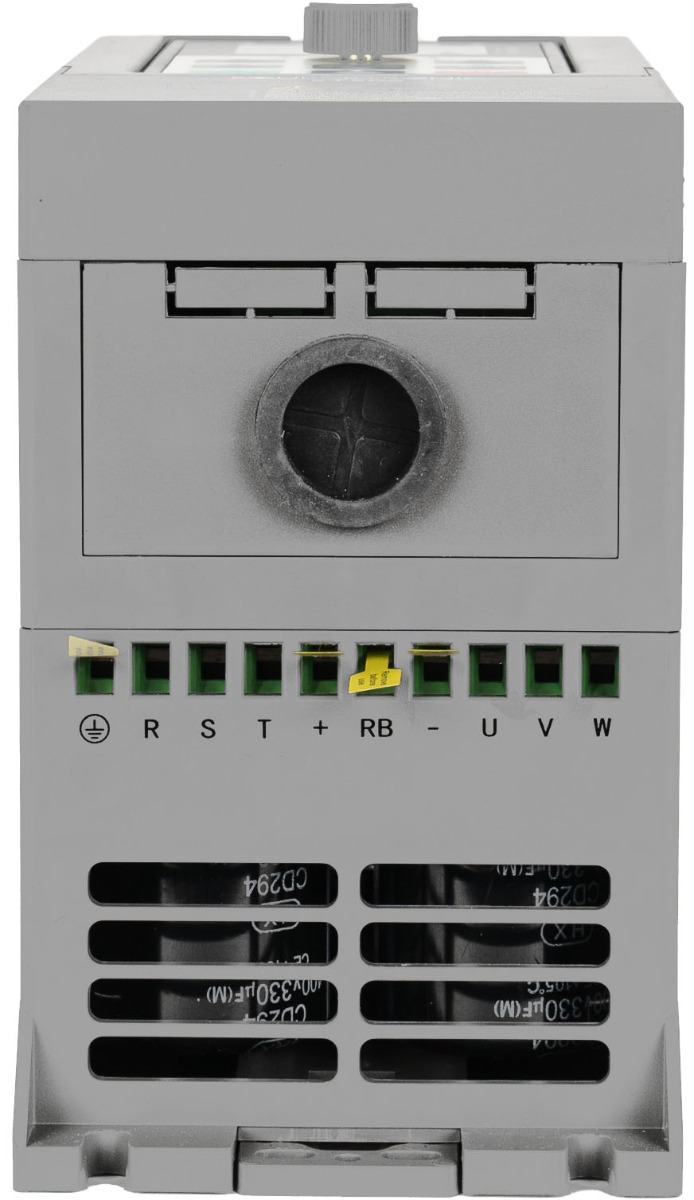

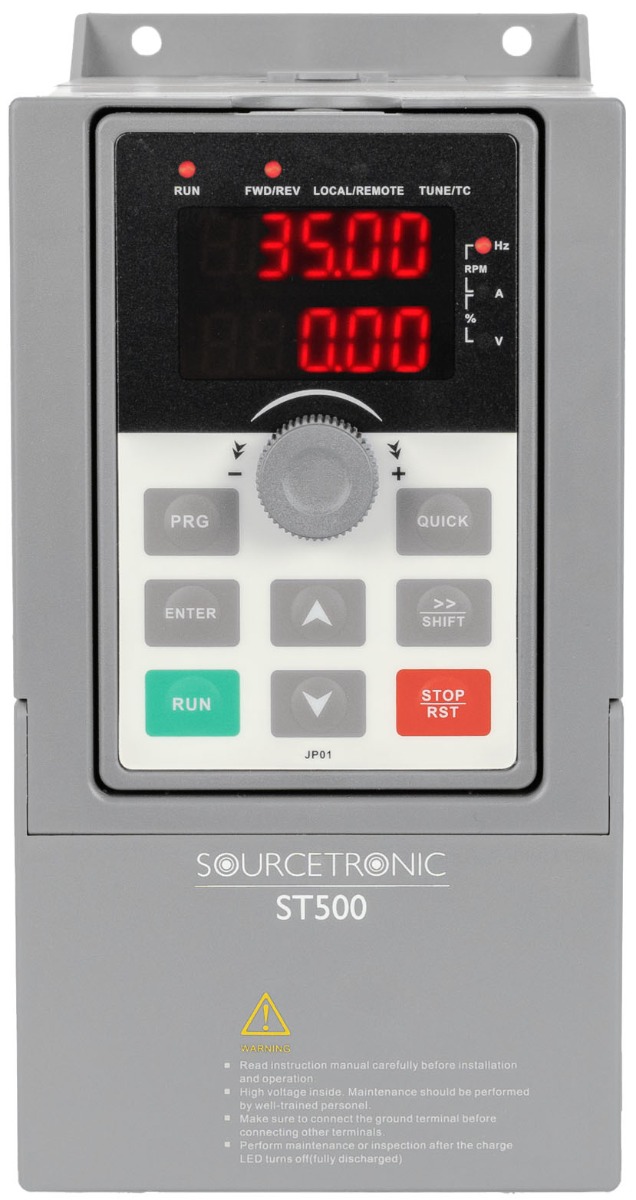

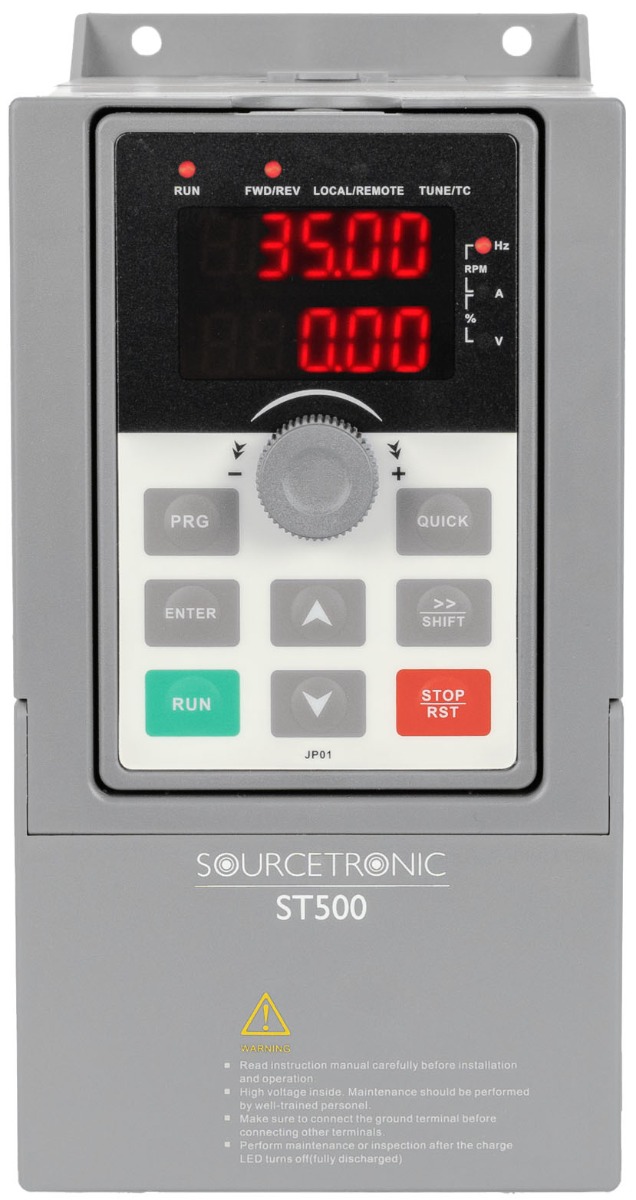

Frequency Inverter ST500 0.75KW - 22KW 400V

From £158.22*

Details

+49 421 277 9999

Product information " Frequency Inverter ST500 0.75KW - 22KW 400V"

Highlights

- Voltage: 380V(-15%) – 440V(+10%)

- Frequency: 50/60Hz, ± 5%

- EMC filter category C3 integrated (from 5,5kw)

- Optimal pre-set of parameters

- Short installation time, easy intuitive start-up operation

- Flexible digital – and analogue I/Os

- Motor speed adjustable by potentiometer

- "Open-Loop-Boost-Mode"

- Auto slip compensation

- Extended PID functions

- Stop-function

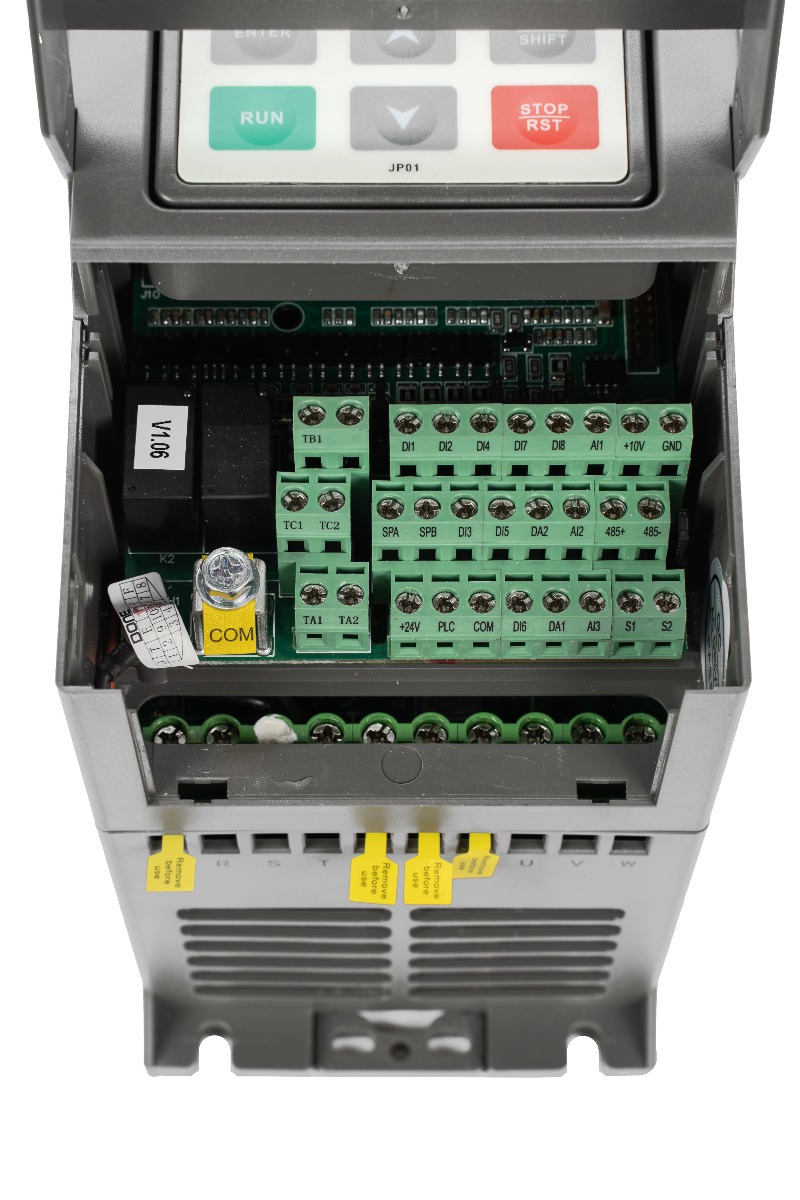

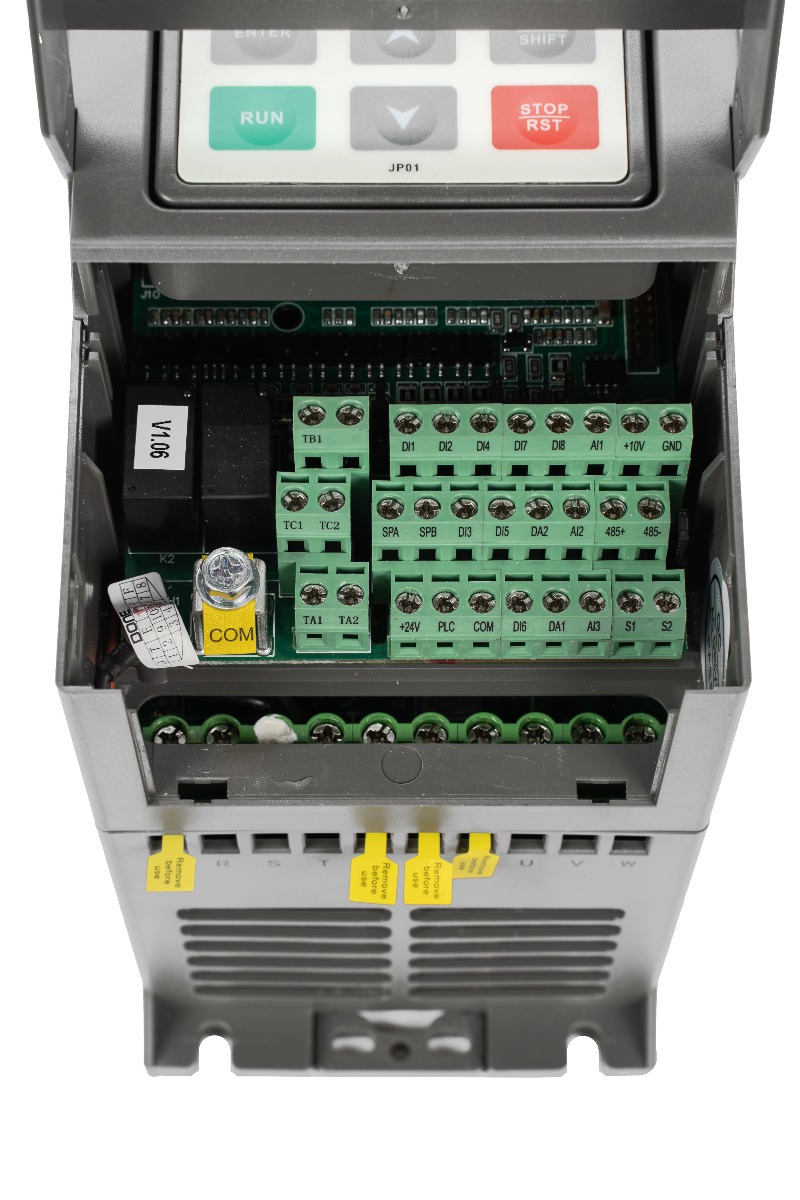

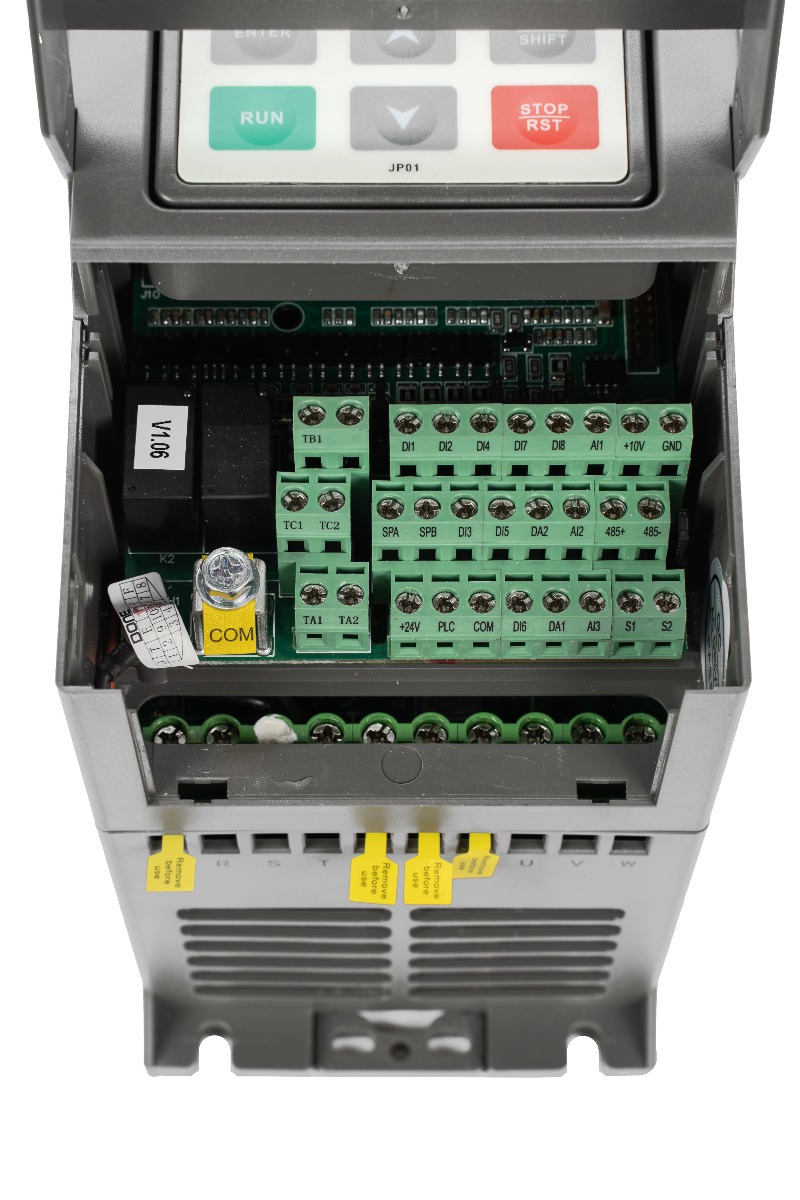

Inputs

Digital Input |

|

| Programmable Digital Inputs: | 8 |

| Voltage: | 0 - 24VDC |

| Logic: | PNP / NPN |

| Max input voltage: | 30VDC |

| Number of programmable pulse inputs: | 1 |

| Max input frequency: | 100kHz |

| Resolution for frequency control: | 0,01Hz (0-320Hz), 0,1Hz (0-3200Hz) |

Analog inputs |

|

| Number of analog inputs: | 3 |

| Type of inputs: | AI 1: 0-10V / 0-20mA AI 2: 0-10V / 0-20mA AI 3:-10-+10V / 0-20mA, PT100 |

| Resolution for frequency control: | max. Frequency * 0,1% |

Outputs

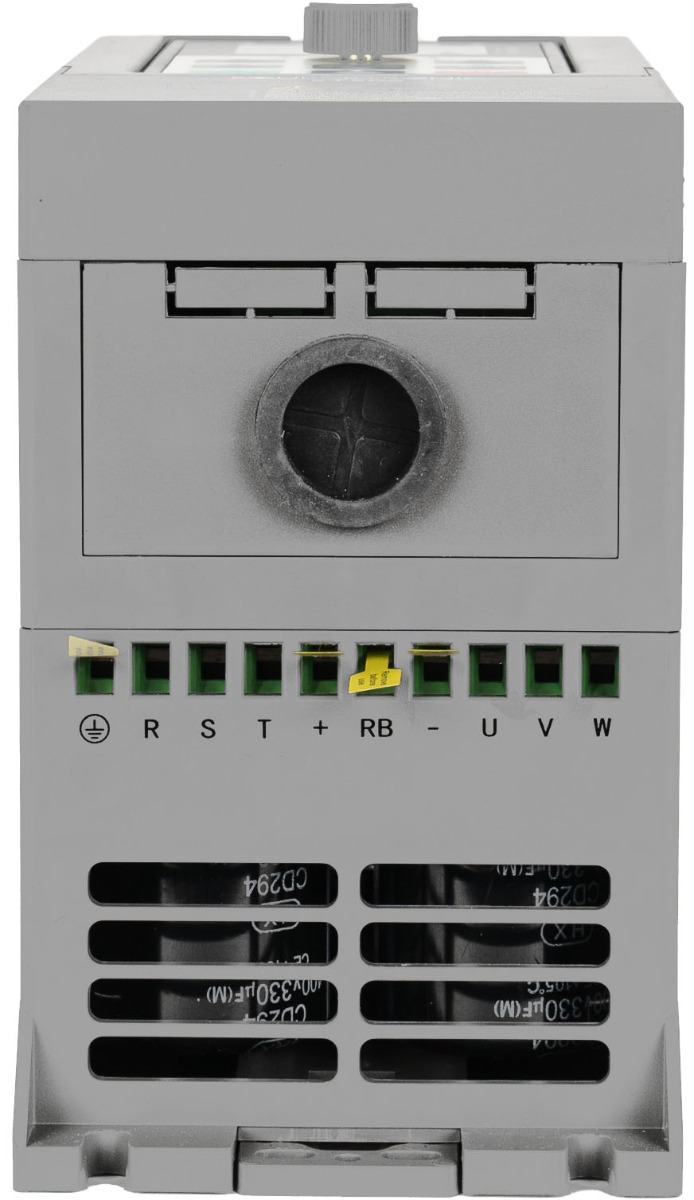

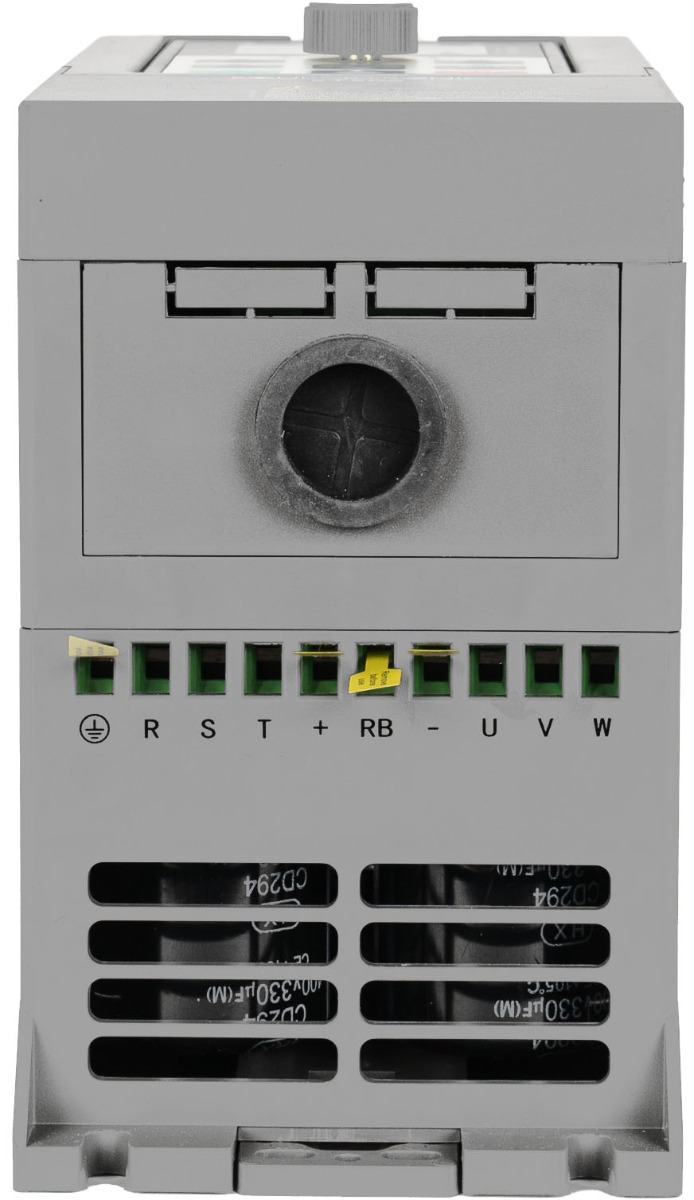

Output (U,V,W) |

|

| Control modes: | V / F characteristic / vector control O. PG / vector control m. PG |

| Output voltage: | 0 - 100% of the power supply |

| Output frequency: | 0 - 300Hz (Vector control) 0 - 3200Hz (V/F - Control) |

| Rated motor voltage: | 400V |

| Ramptimes: | 0,0 - 6500,0s |

| Ramp functions: | Linear / S-Curve |

| Overload functions: | 150% for a minute 180% for 2 seconds |

| Carrier frequency: | 0,5kHz - 16,0kHz adjustable |

| U / f curve modes: | Linear / Square / Adjustable |

Digital output / Pulse output |

|

| Programmable Outputs: | 2 |

| Voltage | 24VDC |

| Logic: | PNP |

| Min. Output frequency: | 0Hz |

| Max. Output frequency: | 100kHz |

Relais outputs |

|

| Programmable Outputs: | 2 |

| Terminal number: | TA1 / TC1 (close) TB1 / TC1 (open) |

| Ma. Power AC: | NO: 250VAC / 5A; NC:250VAC / 3A |

|

Max. Power DC: |

30VDC / 1A |

| Functions: | 39 |

Analog Outputs |

|

| Programmable Outputs: | 2 |

| Voltage: | 0 - 10VDC max. 5mA |

| Current: | 0 - 20mA max. load 250Ohm |

| Functions: | 16 |

Modbus |

|

| RS485 | Integrated |

Technical Data

- Start/Stop-ramp linear: 0.0-6500.0s

- PID feedback signal DC(0-10V), DC(0-20mA)

- Motor nominal frequency 50Hz and 60Hz

- Forward and reverse operation

- Controller release/terminals/Bus

- 16 fixed speeds can be freely set and chosen by input signals

- 10 ways to control speed

- Step less setting of PWM frequency 1kHz-15kHz

- Slots for extensions: special pump control, I/O extension, incremental encoder

- Output frequency:

- Vector control: 0-400Hz

- V/F control: 0-320Hz

- Control mode:

- V/F control (linear, square)

- Vector control W/O PG

- Accuracy: 0.5%

- Speed control:

- Control range 1:100

- Accuracy 0.5%

- Torque:

- Automatic boost for low frequencies down to 1Hz

- Manual increasing 0.1% - 30%

- Response time: <40ms

- Starting torque: 150% from 0.5Hz

- Speed limits adjustable

- Closed-Loop-Technique

- Display:

- Frequency, current, voltage, torque, PID, ...

- Error message

- Keyboard lock

- Automatic functions:

- Indication of motor parameters

- Tension regulation (AVR)

- Zero-Voltage-Switching

- Active current limitation

- Restart after power fail

- Slip compensation

- DC brake function (time, intensity, frequency) & JOG-control

- Reduced motor noises caused by precise PWM-function

- Elegant avoidance of vibrations by blocking frequencies

- Variable speed by continuous torque

- Error memory

- Temperature -10°C up to +40°C above sea level without power reduction

- Storage temperature -20°C up to +65°C

- Humidity 90% RF – without condensation

- Altitude up to 1.000m above sea level without power reduction

- Safety standards in accordance to EN 61800-5-1:2007

- Electromagnetically tolerance in accordance to EN 61800-3:2004+A1:2012

- Vibration test below 5.9m/s² = 0.6g

- Protection class: IP20 (EN 60529), NEMA 1

- RoHS-conform

- CE-conform

Integrated protection concept

- 100 % ground fault protection

- Over- and under-voltage

- Over- and under-current

- Overheating protection

- Over voltage stall

- Overheating protection

- Communication fault

- PID feedback abnormity

- Cooling according to power rating (fan temperature controlled)

- Password protection

- Auto-self testing after restart

- Power failure bypass

I/O interfaces

- Digital and analog I/O - flexible configuration

- 8 digital inputs 9-30VDC (PNP/NPN)

- 3 analog iputs (0-10V / 0-20mA)

- 2 digital output 0-24VDC / 0-40mA

- Pulse output 0-50kHz

- 2 analog input 0-10VDC, 0-20mA

- 2 relay output (250VAC/30VDC, 5A)

- RS485 interface

- IT - ST500 Manuale Sintetico (736.11 KB)

- EN - ST500 Abridged Manual (1.4 MB)

- PL - ST500 Skrócony Podręcznik (713.54 KB)

- NL - ST500 Verkorte Handleiding (1.81 MB)

- FR - ST500 Manuel Abrégé (738.64 KB)

- ST500 EPLAN Makros + DXF (7.92 MB)

- DE - ST500 Kurzanleitung (1.19 MB)

- DK - ST500 Forkortet Manual (1.81 MB)

- ST500 STEP 3D Files (35.92 MB)

- DE - ST500 Quickstart Guide (3.14 MB)

- EN - ST500 User Manual (12.95 MB)

- ES - ST500 Manual Abreviado (737.34 KB)

- DE - ST500 Bedienungsanleitung (12.51 MB)

- DE - ST500 Datenblatt (8.27 MB)

- DE - ST500 Inbetriebnahme Übersicht (83.07 KB)

Accessoires

- Control of a AC-Drive with an Android App via bluetooth

- Devices: ST9000 / ST500 series

- Plug and Play

- Control

- Operating system: Android

- Language: English

- Devices: ST300 (Beta) / ST500 / ST600 series

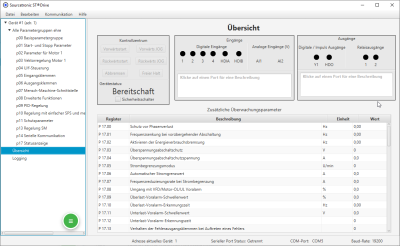

- Clear parameter structure

- Easy changing of parameters

- Parameters can be saved on the PC and printed out via a printer

- Saved parameter files can be reloaded as a backup

- Communication via USB-RS485 adapter cable

- Devices: ST500

- Dimensions (B/H/T): 90/135/22 mm

- 2m cabel inclusive

- Resistance: 750 Ω

- Rated power: 120 W (continuous braking power with appropriate heat dissipation)

- Operating voltage range: up to 400 V

- IP Grade: IP00/IP33

- Weather resistant and vibration resistant

- Easy insatallation

- Telefonische Beratung

- Auslegung und Inbetriebnahme

- Individuelle Parametrierung

- Programmbetrieb

- Parameterliste

- IP20 protection

- Current: 7 A (nominal current must be greater than the input current of the frequency inverter)

- Voltage: 400 V

- Category: C2

- Reduces Voltagepeaks

- Attenuates electromagnetic radiation

- Rated voltage: 3x 400 Vac

- Rated voltage (IEC): 3x 690 Vac

- Rated voltage (UL): 3x 600 Vac

- Short circuit voltage uK: 4% @ 400 Vac

- Voltage drop: 9.2 Vac @ 400 Vac

- Rated current: 3x 63 A

- Rated frequency: 50 - 60 Hz

- Inductance: 0,470mH

- Inductance deviation: ±10%

- Price per meter

- Number of cores and mm² per conductor: 4G1.5 (3x 1.5mm² black and 1x 1.5 mm² PE)

- Outer diameter in mm: 11.4

- Connecting cable for electric drives with high output

- EMC optimized and double shielded

- 3 + 3 symmetry reduces common mode interference

- Installation & Commissioning

- Configuration and parameterisation

- Switch cabinet construction

- Electrification of entire construction sites

- Frequency converter exchange

- Standard-compliant documentation

- Instruction of the operating personnel

- Consulting and design drive technology

- Project planning Electrical engineering

- E-construction ePlan P8

- Programming/visualisation (PLC/HMI/JAVA)

- Monitoring, control and regulation systems

- Sensor consulting

- Processing of tenders with focus on drive technology, automation, pump controls

- Determination of energy saving potentials

- Planning, construction, delivery and installation of control systems

- Frequency Inverter Quick Service

- Installation, commissioning, trial operation

- Instruction of the operating personnel

- Identification of error causes

- Reduction of subsequent and repeat faults

- Maintenance, servicing and retrofitting of systems

- Lifecycle management of drive technology

- Around-the-clock service": 24/7 monitoring service of plants