Frequency Inverter ST300 7.5KW 400V

£332.59*

Details

+49 421 277 9999

Highlights

- Power: 7.5 kW

- Input Current: 28.7 A

- Output Current: 18.5 A

- Input Frequency Range: 50 Hz / 60 Hz ( ± 5%)

- Output Frequency Range: 0 Hz - 599 Hz

- Voltage: 380 V(-15%) – 480 V(+10%)

- “Side-by-side” Mounting: Minimal space requirement due to compact design, easy installation in tight spaces

- Top Entry: Optimal integration into a control cabinet with top entry

- Push-in Terminals: Control wiring terminals are push-in terminals, enabling easy connection

- Shield Mounting Plates: Shielded cables can be mounted EMC compliantly on the top and bottom

- STO: Every frequency inverter in the ST300 series features the STO safety function (SIL3, PLe)

- German User Manual: A highly detailed German user manual is available for free download

- First-class technical support from experts, comprehensive user manual, and helpful FAQs

- Integrated C3 filter, higher level possible simply via external filters

- Modbus RTU: The frequency inverter features an RS485 interface with the Modbus-RTU standard

- Adjustment options: Over 40 digital input functions, over 20 digital output functions, and over 20 analog output functions

Scope of Delivery

- ST300 Frequency Inverter

- Shield Plate C

Technical Specifications

Network Properties |

|

| Input Voltage: | AC 3~ 380V (-15%) to 480V (+10%) |

| Rated Power: | 7.5 kW |

| Input Rated Current (at 380V): | 28.7 A |

| Input Frequency: | 50Hz or 60Hz ±5%, with a maximum change rate of 20%/s |

| Integrated EMC Filter Class: | C3 |

Motor Connection Data |

|

| Control Modes | V/f Characteristic / Open Loop Vector Control |

| Output Voltage: | 0 - 100% of Supply Voltage |

| Output Current: | 18.5 A |

| Output Frequency: | 0 - 599Hz |

| Ramp Times: | 0.0 - 3600.0s |

| Ramp Functions: | Linear / S-Curve |

| Overload Function: | 150% for one minute180% for 10 seconds |

| Carrier Frequency: | 1kHz - 15kHz adjustable |

| V/f Curve Modes: | Linear / Quadratic / Adjustable |

| Braking Unit: | Integrated (external braking resistor possible) |

| Type of Motor: | Asynchronous Induction Motor or Permanent Magnet Synchronous Motor |

Digital Inputs |

|

| Programmable Digital Inputs: | 6, of which 4x max. 1kHz (S1-S4), 1x max. 50kHz (HDIA)with 42 input functions |

| Voltage Level: | 0 - 24VDC |

| Logic: | NPN (active when input is connected to GND) |

| Maximum Voltage at Input: | 30VDC |

| Number of Programmable Pulse Inputs: | 1 (HDIA) |

| Maximum Input Frequency: | 50kHz, duty cycle 30 to 70% |

| Resolution for Frequency Control: | 0.1% |

| Safety STO: | Redundant inputs for connection to +24V via NC contacts for the safety function STO (immediate interruption of power supply to the drive when at least one of the connections to +24V is interrupted). Factory connected to +24V via shorting links (STO inactive). |

Digital Outputs |

|

| Programmable Outputs: | 1 Open-Collector output, max. 1kHz |

| Voltage Level: | 24VDC, max. 30VDC, 50mA |

| Logic: | NPN (output is active against GND) |

| Minimum Output Frequency: | 0Hz |

| Maximum Output Frequency: | 1kHz |

| Number of Functions: | 25 |

Relay Outputs |

|

| Programmable Outputs: | 1 |

| Terminal Number: | RO1A: NO; RO1B: NC; RO1C: Common (Root Contact) |

| Maximum Power AC: | 250VAC / 3A |

| Maximum Power DC: | 30VDC / 1A |

| Number of Functions: | 26 |

Analog Inputs |

|

| Number of Analog Inputs: | 2 |

| Type of Inputs: | AI 1: 0-10V / 0(4)-20mA AI 2: -10 to +10V |

| Resolution for Frequency Control: | max. frequency * 0.05%, tolerance ±0.5%@25°C |

Analog Outputs |

|

| Programmable Outputs: | 1 |

| Voltage Range: | 0 - 10VDC max. 5mA |

| Current Range: | 0(4) - 20mA |

| Number of Functions: | 23 |

Communication |

|

| RS485 (RTU) | Integrated |

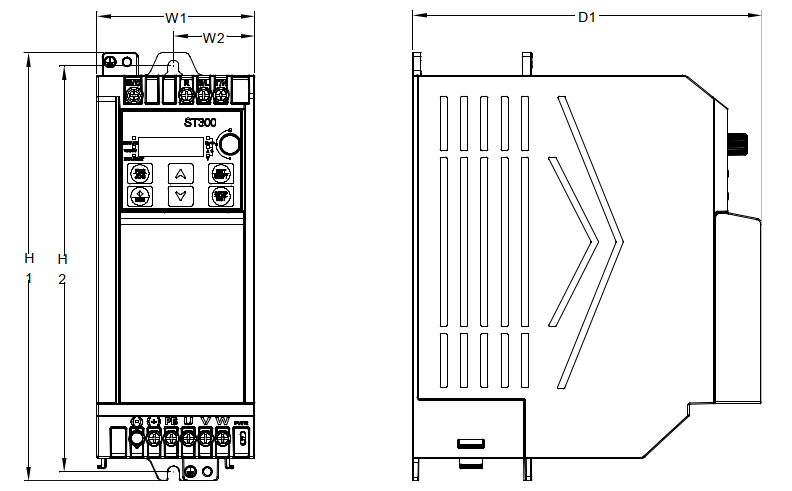

Dimensions, Weight |

|

|

|

| DimensionsW1 x H1 x D1(W x H x D) | 90mm x 235mm x 155mm |

| Mounting Hole Spacing | W2 = 70mmH2 = 220mm |

| Mounting Hole Diameter | 6 mm |

| Net Weight: | 1.95 kg |

Environmental Requirements |

|

| Operating Environment Temperature: | -10°C to 50°C: no derating required; Note: Derating becomes necessary when the ambient temperature exceeds 50°C. For further details, see the operating manual |

| Protection Class: | IP20 |

| Altitude: | Lower than 1000m, when exceeding 1000m, reduce the power by 1% per 100m altitude. |

| Vibration: | Max. Vibration ACC: 5.8m/s2 (0.6g) |

| Installation Direction: | Vertical |

| Relative Humidity (RH) | <90% |

Standards |

|

| EN/ISO 13849-1 | Safety of Machinery – Safety-Related Parts of Control SystemsPart 1: General Principles for Design |

| EN/ISO 13849-2 | Safety of Machinery – Safety-Related Parts of Control SystemsPart 2: Validation |

| IEC/EN 60204-1 | Safety of Machinery – Electrical Equipment of MachinesPart 1: General Requirements |

| IEC/EN 62061 | Safety of Machinery – Functional Safety of Electrical, Electronic, and Programmable Electronic Control Systems |

| IEC 61800-3:2018 | Adjustable Speed Electrical Power Drive SystemsPart 3: EMC Requirements and Specific Test Methods |

| IEC/EN 61800-5-1 | Adjustable Speed Electrical Power Drive SystemsPart 5-1: Safety Requirements – Electrical, Thermal, and Energy |

| IEC/EN 61800-5-2 | Adjustable Speed Electrical Power Drive SystemsPart 5-2: Safety Requirements – Function |

- NL - ST300 Verkorte Handleiding (1.04 MB)

- EN - ST300 Quick Start Guide (26.3 MB)

- EN - ST300 User Manual (37.78 MB)

- DE - ST300 Bedienungsanleitung (15.78 MB)

- PL - ST300 Skrócony Podręcznik (836.37 KB)

- IT - ST300 Manuale Sintetico (1025.55 KB)

- DK - ST300 Forkortet Manual (835.15 KB)

- DE - ST300 Quick Start Guide (26.3 MB)

- ES - ST300 Manual Abreviado (813.98 KB)

- FR - ST300 Manuel Abrégé (802.98 KB)

- DE - ST300 Kurzanleitung (1.82 MB)

Accessoires

- Devices: ST300 (Beta) / ST500 / ST600 series

- Clear parameter structure

- Easy changing of parameters

- Parameters can be saved on the PC and printed out via a printer

- Saved parameter files can be reloaded as a backup

- Communication via USB-RS485 adapter cable

- Telefonische Beratung

- Auslegung und Inbetriebnahme

- Individuelle Parametrierung

- Programmbetrieb

- Parameterliste

- Large shield mounting for motor cables

- Simple and efficient shielding connection

- Suitable for ST300 frequency inverters from 5.5 kW - 7.5 kW

- IP20 protection

- Current: 30 A (nominal current must be greater than the input current of the frequency inverter)

- Voltage: 400 V

- Category: C2

- Reduces Voltagepeaks

- Attenuates electromagnetic radiation

- Resistance: 75 Ω

- Rated power: 800 W (continuous braking power with appropriate heat dissipation)

- Operating voltage range: up to 400 V

- IP Grade: IP00/IP33

- Weather resistant and vibration resistant

- Easy insatallation

- Rated voltage: 3x 400 Vac

- Rated voltage (IEC): 3x 690 Vac

- Rated voltage (UL): 3x 600 Vac

- Short circuit voltage uK: 4% @ 400 Vac

- Voltage drop: 9.2 Vac @ 400 Vac

- Rated current: 3x 30 A

- Rated frequency: 50 - 60 Hz

- Inductance: 0,980mH

- Inductance deviation: ±10%

- Rated voltage: 3x 400 Vac

- Voltage range: 3 x 0 - 500 Vac

- Rated current: 18 A

- for motor rated output approx. 7,50 kW

- Inductance: 0,350 mH

- Rated frequency: 0 - 50 Hz

- Switching frequency: 3 - 8 kHz

- Rated voltage: 3 x 400 Vac

- Voltage range: 0 - 520 Vac

- Voltage drop: 7.5% @ 400

- Rated current: 16.5A

- for motor rated output approx. 7,5kW

- Rated frequency: 0 - 150 Hz

- Switching frequency: 4 - 8 kHz

- Price per meter

- Number of cores and mm² per conductor: 4G4 (3x 4mm² black and 1x 4 mm² PE)

- Outer diameter in mm: 15.6

- Connecting cable for electric drives with high output

- EMC optimized and double shielded

- 3 + 3 symmetry reduces common mode interference