-

Measurement Technology

-

Battery tester

-

Calibration Services

-

Capacitance Meter

-

DC Bias Current Source

-

Digital Power Meter

-

Earth Tester

-

Ground Bond Tester

-

HV Probe

-

High Voltage Relays

-

Hipot tester

-

Impedance Analyzer

-

Insulation Tester

-

LCR Meter

-

Measurement Software

-

Megohmmeter

-

Microohmmeter

-

Milliohmmeter

-

Multimeter

-

Relay Matrix

-

Rental Equipment

-

Safety Tester

-

Surge Tester

-

Test Systems

-

Transformer Tester

-

Transport Cases

-

Battery tester

Certified quality management system

Modular Test System ST400

Price on request

Details

+49 421 277 9999

Product information "Modular Test System ST400"

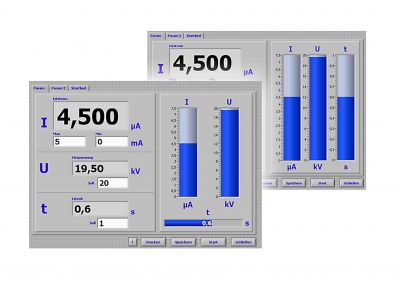

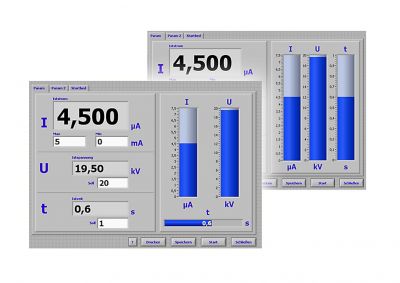

Modular Test System ST400

The modular electrical safety tester ST400 can be fitted with diferent test modules such as high voltage, insulation, protective earth, leakage current, function test and many more. Due to this flexibility the tester can perform a great number of norm tests for example VDE, EN or UL norms.

The safety tester can be both remote controlled and operated directed on the device. Depending on the application the ST400 can be supplied with different operating variants. Available are 2 TFT touch displays in different sizes and a remote version without a own display. A complete industrial PC can be integrated as well to replace a PC for the test system. The tester has both optional USB and LAN interfaces to store result data and test plans on a USB Stick and in the local network.

There are several different drivers available to realize a complete remote control. The drivers and libraries include LabView, DLL, ASCII, .NET-Framework and Active-X. The driver packages also include programming support from our staff to help implement the ST400 in your test system.

The wide range of accessories includes both a wide range of adaptation options, as well as trolley and safety accessories.

Electrical safety and norms

| EN 61010-1 | safety regulations for electrical measurement, control- and lab- equipment |

| EN 61326-1 | electrical measurement, control- and lab- equipment – EMC-requirements |

| EN 61000-3-3 / EN 61000-3-2 | Electromagnetic compatibility (EMC) |

| EN 50191 | Erection and operation of electrical test equipment |

| EN 60598-1 | luminaire / Part 1: General requirements and tests |

| Contamination level | 2 |

| Protection class | 1 |

General specifications |

|||

| Power connection: | 230 V, 50 Hz / 60 Hz | ||

| Input voltage range: | +/- 10 % | ||

| Power consumption: | Max. 10 A, depending on the type up to 16 A | ||

| Type X2: | without Display | ||

| Type X4: | TFT-Display with Touch 5,7 inches, 640 x 480 | ||

| Type X5: | TFT-Display with Touch 10,4 inches, 800 x 600 | ||

| Type X6: | without Display, with VGA- connection | ||

| Type X8: | TFT-Display with Touch 10,4 inches, 800 x 600 | ||

| Setting the test parameters: | Manually or fully automatically via interface | ||

| Programming: | Via display or external control | ||

| Testplan and parameter saving: | Internal hard drive, LAN or USB | ||

| Error signal: | Acoustically, optically or via interface | ||

| Dimensions (W x H x D): | 410 x 210 x 435 mm | ||

| Weight: | From ca. 18 – 35 kg | ||

| Casing: | Metal, light grey | ||

| Temperature range: | 5 - 45 °C | ||

| Basic equipment: | Instruction manual, main cable, safety circuit plug | ||

| Calibration: | Factory calibration certificate inclusive | ||

Environmental conditions |

|||

| Protection level: | IP20 | ||

| Relative humidity | max. 80 %, non-condensing | ||

| Operating Temperature | + 5 up to + 40 °C | ||

| Cooling: | Active cooling | ||

Interfaces |

|||

| ST Interface, digital: | Start, stop, result good / error and test in process, etc. | ||

| Optional: USER Interface, digital: | Freely configurable IOs | ||

| Optional: ADF Interface: | Analogue IOs and frequency inputs | ||

| Remote control interface RS232: | For the connection to the PC and for direct connection to a terminal programme or a log printer | ||

| USB: | For Keyboard connection, mouse and barcode scanner | ||

| LAN: | For establishing a connection to a server or a local network | ||

| CAN: | For the expansion of the test system, for additional features und further expansion stages | ||

Connections |

|||

| High voltage outputs: | The contacting of the test object is executed via 2 potential-free high voltage outputs, each double-pole with connection jack for an HVP06C plug. | ||

| PE Test probe: | Connection for contacting the test objects via a test probe with start push button and result-LEDs. | ||

| Safety circuit: | For the implementation of the suitable safety circuit according to EN 50191 | ||

| Warning light connection: | For the connection of a warning light combination according to EN 50191 | ||

Starting the Test |

|||

| Start and stop signal by a test pistol: | Via a special automatic choke and 4-pole technology | ||

| Start button on the device: | Starting the test with a button at the front of the device | ||

| Start and stop signal via interface: | Starting the test via PLC or PC-interface | ||

| Start button via an external switch: | Starting the test via digital IO, e.g. via foot switch | ||

Setup |

|||

| Keyboard lock: | Individually configurable | ||

| Output options: | Individual configuration of the result outputs | ||

| Buzzer options: | Individual configuration of the acoustic signals | ||

| Start options: | Individual setting of the start mode | ||

| Language and mode selection for an external printer: | English, German, Swedish, Italian, Spanish, Dutch / mode: printout at I.O., not N.I.O. or all the times | ||

| Ramp options: | Ramp time and kind of the ramp decrease | ||

| Test time: | Test time scaling | ||

Test time |

|||

| Setting range: | 0,5 – 6 000 s | ||

| Resolution: | 0,01 s | ||

Related products

- Devices: series 36 & 400

- Complete library

- License for 1 test system

- Including CD with drivers and manual

- Devices: series 36 & 400

- Complete library

- License for 1 test system

- Including CD with drivers and manual