Frequency Inverter buy, rent & parameterize

Frequency inverters for motors, drives, gearboxes and pumps

In the ST- Shop you can buy high-quality frequency inverters in the power range from 0.75kW to 1000kW. You will find different model series, which are suitable for different applications. Sourcetronic offers beside the proven products also product novelties, to which you can be advised by the expert.

Buy frequency inverters online now:

- Only suitable for 3-phase motors

- Input voltage range single-phase: 220V (-15%) – 240V (+10%)

- Input frequency range: 50Hz / 60Hz (± 5%)

- Output frequency range: 0 - 300Hz / 0 - 3200Hz

- Motor voltage three-phase: 0 - 230V

- Comprehensive German user manual

- Side-by-side mounting

- Detachable two-line display

- Integrated connection for motor temperature contact

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control & PID regulation

- Input voltage range three-phase: 380V(-15%) - 440V(+10%)

- Input frequency range: 50/60Hz (±5%)

- Output frequency range: 0 - 300Hz / 0 - 3200Hz

- Comprehensive German user manual

- Side-by-side mounting

- Detachable two-line display

- Integrated connection for motor temperature contact

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control & PID regulation

- Integrated EMC filter category C3 (from 5.5kW)

- Input voltage range three-phase: 380V(-15%) - 440V(+10%)

- Input frequency range: 50/60Hz (±5%)

- Output frequency range: 0 - 300Hz / 0 - 3200Hz

- Comprehensive German user manual

- Side-by-side mounting

- Detachable two-line display

- Integrated connection for motor temperature contact

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control & PID regulation

- Integrated EMC filter category C3

- Input voltage range three-phase: 380V(-15%) - 440V(+10%)

- Input frequency range: 50/60Hz (±5%)

- Output frequency range: 0 - 300Hz / 0 - 3200Hz

- Comprehensive German user manual

- Side-by-side mounting

- Detachable two-line display

- Integrated connection for motor temperature contact

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control & PID regulation

- Integrated EMC filter category C3

- Input voltage range three-phase: 380V(-15%) - 440V(+10%)

- Input frequency range: 50Hz / 60Hz ( ± 5%)

- Output frequency range: 0 - 400Hz

- Comprehensive German user manual

- Emergency stop function according to SIL2 level (STO)

- Graphical detachable LCD control panel

- Expandable with WIFI, Bluetooth, ProfiNet/Profibus, CANopen, PG, PLC, IO

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control and PID regulation

- Integrated EMC filter category C3

- Input voltage range three-phase: 380V(-15%) - 440V(+10%)

- Input frequency range: 50Hz / 60Hz ( ± 5%)

- Output frequency range: 0 - 400Hz

- Comprehensive German user manual

- Emergency stop function according to SIL2 level (STO)

- Graphical detachable LCD control panel

- Expandable with WIFI, Bluetooth, ProfiNet/Profibus, CANopen, PG, PLC, IO

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control and PID regulation

- Integrated EMC filter category C3

- Input voltage range three-phase: 380V(-15%) - 440V(+10%)

- Input frequency range: 50Hz / 60Hz ( ± 5%)

- Output frequency range: 0 - 400Hz

- Comprehensive German user manual

- Emergency stop function according to SIL2 level (STO)

- Graphical detachable LCD control panel

- Expandable with WIFI, Bluetooth, ProfiNet/Profibus, CANopen, PG, PLC, IO

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control and PID regulation

- Integrated EMC filter category C3

- Input voltage range three-phase: 380V(-15%) - 440V(+10%)

- Input frequency range: 50Hz / 60Hz ( ± 5%)

- Output frequency range: 0 - 400Hz

- Comprehensive German user manual

- IP55 protection class

- Emergency stop function according to SIL2 level (STO)

- Graphical detachable LCD control panel

- Expandable with WIFI, Bluetooth, ProfiNet/Profibus, CANopen, PG, PLC, IO

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control and PID regulation

- Integrated EMC filter category C3

- Input voltage range three-phase: 380V(-15%) - 440V(+10%)

- Input frequency range: 50Hz / 60Hz ( ± 5%)

- Output frequency range: 0 - 400Hz

- Comprehensive German user manual

- IP55 protection class

- Emergency stop function according to SIL2 level (STO)

- Graphical detachable LCD control panel

- Expandable with WIFI, Bluetooth, ProfiNet/Profibus, CANopen, PG, PLC, IO

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control and PID regulation

- Integrated EMC filter category C3

- Only suitable for 3-phase motors

- Input voltage range single-phase: 200 V(-15%) – 240 V(+10%)

- Input frequency range: 50 Hz / 60 Hz ( ± 5%)

- Output frequency range: 0 Hz - 599 Hz

- Motor voltage three-phase: 0 - 230V

- Comprehensive German user manual

- STO: Standard-compliant emergency stop function according to SIL3 level

- Shield grounding plates

- Side-by-side mounting

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control and PID regulation

- Integrated EMC filter category C3

- Input voltage range three-phase: 380 V(-15%) – 480 V(+10%)

- Input frequency range: 50 Hz / 60 Hz ( ± 5%)

- Output frequency range: 0 Hz - 599 Hz

- Comprehensive German user manual

- STO: Standard-compliant emergency stop function according to SIL3 level

- Shield grounding plates

- Side-by-side mounting

- Flexible digital and analog I/Os

- Modbus RTU interface

- Precise vector control and PID regulation

- Integrated EMC filter category C3

- Power: 2.2 KW

- Rated input current: 23 A

- Rated output current: 10 A

- Voltage: 230VAC (220V-15% - 240V+10%, mains: 1-phase/motor: 3-phase).

- Mains frequency: 50/60Hz, +-5%.

- German instruction manual

- Weight: 1.1 Kg

- Dimensions (H/W/D): 185 / 72 / 134 mm

- Top-hat rail mounting

- "Plug & Play"

- Voltage 500V 3-phase/3-phase (mains/motor)

- Digital- and analogue I/O's

- Extended PID control

- Overload ability: 1min. 150% / 2 sec. 180%

- Automatically identification of motor parameters

- Integrated protection concept

Sourcetronic expertise on frequency inverters

The frequency converter is an important instrument within electrical engineering. It is a so-called power converter that can convert electrical currents with different frequencies and voltages into each other. For example, a three-phase output voltage with variable frequency can be generated from a single-phase mains supply. This is useful, for example, if you want to operate three-phase motors. In this case, you should always use a high-quality frequency converter, as this ensures a consistently high quality of the motor supply in different operating states and always provides the frequency and voltage required for the desired speed. This is extremely important so that three-phase motors are not restricted in their performance and have a long service life. By adapting the frequency and voltage to the demand, significant energy savings can be achieved compared to direct connection to the mains. In addition, the continuous change in frequency during acceleration and braking results in improved running smoothness.

Important information about frequency inverters can be found here:

- Video: Quickstart Guide for ST500 Inverters

- How do I connect a frequency inverter?

- Accessories and spare parts: Software, Bluetooth bundle, etc.

- Repair service for inverters in the ST-Shop

- Frequency inverters and their possible applications

- What to look for when buying a frequency inverter

- Frequency inverter feature comparison - All Sourcetronic inverters in comparison

- FAQ: Help and tips

Watch the video: Quickstart Guide for ST500 inverters

In this Quickstart video you will find information on how to quickly and safely connect your Sourcetronic AC drive correctly.

How do I connect a frequency inverter?

With a few simple steps you can connect any inverter from the Sourcetronic Shop. Here you will learn how to do it using the ST500 as an example and what you should pay attention to.

- Open the housing at the lower edge of the inverter by removing both flaps. You will now see the control terminals (top) and the power terminals (bottom).

- Connect the mains supply cables, i.e. for a single-phase 230 V G1 inverter, connect the phase and neutral conductor to the terminals "R" and "T". You do not have to pay attention to the phase position. Connect the protective earth conductor to the earth terminal on the right-hand side of the terminal strip. If you have a 400 Volt G3 inverter, you must use the terminals "R", "S" and "T" for the three phases. The neutral wire is not required.

- Switch on the power supply and the display will show you the number 50. This number stands for 50 Hertz. If everything works properly, you should disconnect the frequency converter from the mains again.

- Now attach the motor directly to the inverter. Use the "U", "V" and "W" terminals and the earth terminal for this.

- Switch the mains on again. You can now start and stop the motor using the control panel and adjust the frequency using the dial.

Tip: You can simply remove the control panel and then extend it using a LAN cable. This way you do not have to be in the immediate vicinity of the frequency converter and can also control it remotely.

Accessories and spare parts: software, Bluetooth bundle, etc.

In the ST Online Shop you will find a wide range of suitable accessories and spare parts for your frequency inverter. Depending on the desired use, there are different accessories that you can order online.Among the most popular products and services are mainly the following:

- Software for frequency inverters:With these accessories, such as the ST®Drive software, you can parameterize and commission all frequency inverters from the ST Shop.

- Control panel mounting frame: Allows you to place the control panel of the inverter in a different location, such as in the door of the control cabinet.

- Extension cable: The two-meter cable allows you to operate the frequency inverter from a greater distance.

- Bluetooth bundle: This accessory set ensures that you can make settings practically via Bluetooth.

- Advice on drive technology: With this service, Sourcetronic consultants can help you over the phone. First-class trained and experienced technicians are happy to advise you. Individual parameterizations as well as support for special applications are also covered by this service.

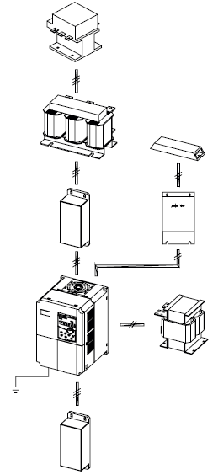

- A wide range of brake resistors, EMI filters, sine wave filters as well as reactors

- Other spare parts and accessories: interface extensions, pressure transmitters for overpressure, encoder cards, interface inverters and much more.

Buy accessories in the ST- Shop that meet the highest and most modern standards. The spare parts are easy to assemble, which allows you a quick start-up. If you have any questions, the ST team will of course be happy to help you at any time.

Repair service for inverters in the ST shop

If problems occur when using a device, we will be happy to help you. The ST repair service also takes care of defective devices of all kinds, including frequency inverters purchased from Sourcetronic. You can make use of the service at any time if you want to have a frequency converter repaired. This way faults can be found quickly. The team will take care of your request as quickly as possible, as well as repairing the defective inverters so that they can be used again as soon as possible.Simply contact the technical advisors as soon as you notice a problem with your frequency inverter. Use the contact form to make an enquiry. Minor faults can often be rectified quickly. Defective individual parts can be replaced quickly and easily.

Frequency inverters and their possible areas of application

The use of frequency inverters is unavoidable in many industries. Thus, a large number of companies within the industry work with the inverters. In the following you will find some examples of the use of frequency inverters:

- Within control engineering, in order to be able to implement control systems. Here the inverter is controlled remotely by a PLC.

- In plant construction and conveyor technology as well as in automation.

- In the automotive industry, for controlling machines.

- Drive of motors, for example for stepless speed control of asynchronous and synchronous three-phase motors.

- In the field of pump controls or motor controls, to regulate a pump/motor.

- For controlling the speed or torque with voltage/frequency control or space vector modulation.

For each application it is extremely important that you pay attention to the product documentation. This is particularly important during installation. Only with the help of the instructions can you make the correct settings. In addition to installation and connection, this is particularly necessary for input and output voltage, the circuit diagram and programming. It is important that you have the frequency inverter set up by a specialist, for example to carry out level control.

What to look for when buying a frequency inverter

When buying a frequency converter, there are a number of things you should look for to ensure that you get a safe product that is suitable for your purposes. There is a wide variety of inverters on the market, each suitable for a different application. Therefore, be sure to compare the different models with each other to find the one that is right for you before you buy the frequency converter. At ST Shop, you will find high-quality solutions with sophisticated technology for any industry that operates in the field of electronics. Here you can see the main features that our frequency inverters have in common:

- The inverters are usually suitable either for single-phase mains voltage of 230 V as well as for three-phase motor voltage of also 230 V or for three-phase mains voltage as well as motor voltage of 400 V.

- These are devices that are easy to operate, but still have a functional performance.

- With the corresponding certificates, you receive a safe frequency converter.

- The inverters convince with an integrated automation, which makes your work much easier. Many control tasks can thus be solved without an additional PLC.

- The high energy efficiency of the ST frequency inverters ensures low costs during use. Depending on the model, efficiency ranges from 97% to over 98%.

Functionality and performance are Sourcetronic's top priorities, which is why you can order only the best frequency inverters the market has to offer in the ST Online Shop. The experts are available to advise you on all questions regarding your purchase. You can also count on the drive technology team afterwards when it comes to the installation, configuration, maintenance and repair of your inverters. Simply contact the specialist consultants without obligation and find out more about the frequency inverters from the ST range.

Frequency inverter feature comparison - All Sourcetronic inverters in comparison

| Features | ST150 | ST300 | ST500 | ST600 | ST600SP |

|---|---|---|---|---|---|

| Power Range/kW Voltage Range |

0.75 - 2.2 kW - 230 V | 0.75 - 7.5 kW - 230 V | 1.5 - 500 kW - 400 V | 4 - 55 kW - 400 V | |

| 0.75 - 2.2 kW - 400 V | 0.75 - 7.5 kW - 400 V | 0.75 - 710 kW - 400 V | |||

| 0.75 - 132 kW - 500 V | |||||

| 15 - 132 kW - 690 V | |||||

| Control Mode | U/f Control | ||||

| Vector Control without PG | |||||

| Vector Control with PG | |||||

| Number of Analog Inputs | 1 | 2 | 3 | 2 | |

| Number of Analog Outputs | 1 | 2 | 1 | ||

| Number of Digital Inputs | 5 (NPN) | 8 | 6 | ||

| Number of Digital Outputs | 0 | 1 (NPN) | 2 (NPN) | ||

| Number of Relay Outputs | 1 (Normally Closed Contact) | 2 (1 Changeover Contact, 1 Normally Closed Contact) | |||

| Security Function | No | STO (SIL3, PLe) | No | STO (SIL2) | |

| Control Panel | Non-removable | Removable | Non-removable | ||

| Motor Types | Three-phase Asynchronous Motors | ||||

| Synchronous Motors | Synchronous Motors | ||||

| Communication | RS485 (Modbus RTU Protocol) | ||||

| Profibus DP | |||||

| CANopen | |||||

| PROFINET | |||||

| Ethernet/IP | |||||

| Modbus TCP | |||||

| Protection Class | IP 20 | IP 55 | |||

| Built-in EMC Filter | C3 Filter | C3 Filter: Standard integrated from 5.5 kW, switchable from 15 kW (default setting: Off) | C3 Filter | ||

| Motor Temperature Monitoring | No | PTC | |||

| PT100 | PT100 with expansion card | ||||

| PT1000 | PT1000 with expansion card | ||||

| Possible Side-by-Side Mounting with Narrow Side Clearance | Yes | Yes, size-dependent | No | ||

| Possible DIN Rail Mounting | Yes | With DIN rail adapter | For 230 V devices up to and including 2.2 kW For 400 V devices up to and including 4 kW |

No | |

| Integrated Brake Unit | Yes | Up to 22 kW | Up to 37 kW | Yes | |

| Special Features | Top Feed-in | Shield Support Plates | Expansion Options (Communication, I/O, Encoder Cards) | ||

| Top Feed-in | Integrated Main Switch | ||||

| Control Panel Potentiometer | No | Yes | Digital Control Panel Rotary Encoder | No | |

| Display | 1-line 7-Segment Display | 2-line 7-Segment Display | Multilingual LCD Display | ||

| Control Terminal Connection | Screw Terminals | Push-In Terminals | Screw Terminals | ||

FAQ: Assistance with typical problems

When dealing with technical equipment, questions arise again and again. The frequency inverter is no exception. However, there are quick solutions for many problems in dealing with the inverters. It is not always necessary to contact ST Support or the repair service. First of all, it is helpful to consult all materials in the technical documentation, such as the manuals, especially the chapters on installation and commissioning and the troubleshooting tips. A look at the ST FAQ will also help you quickly. In addition to general questions about the frequency inverters, you will also find special assistance there which may apply to your current problem. Before contacting us, it is recommended to have a look at the FAQ articles below. It is possible that a solution for exactly the problem that currently occurs with your device is described there. In addition to the questions, you will also find instructions that you can use in case of a specific error code. It is therefore extremely important that you make a note of the error codes as soon as they occur. This will also help the ST team to narrow down the error when you contact support. If you can't find what you're looking for on the ST page or have any further questions, don't hesitate to contact customer service immediately. The Drive Technology team will be happy to help you if you have any questions about your frequency inverter.

ST500 | Wiring diagram

ST500 | How do I commission the ST500 frequency inverter?

ST500 | Analog output signals – for example, for motor voltage, motor current, motor power

ST500 | Braking and acceleration times

ST500 | Limit starting current e.g. for fan motors

ST500 | Introduction to Operating: By Changing the Target Frequency

ST500 | DC braking to hold engine into position

ST500 | External Potentiometer – How to connect it and which one is compatible?

ST500 | Initial operation – What should I watch for (motor data)?

ST500 | Power Class – Which Model Do I Need?

ST500 | Minimum Frequency for External Potentiometer

ST500 | Activate Panel Potentiometer – Control Motor Frequency via Dial

ST500 | Pump Control

ST500 | Program Sequences – PLC Programming

ST500 | Multi-speed function – Simple frequency or change of rotating direction

ST500 | Keep last frequency after resetting

ST500 | Forward, reverse, stop – Which parameter and terminal assignment?

ST500 | Target frequency over 320Hz

ST500 | Forward, reverse, stop with buttons

ST500 | Forward and reverse with panel potentiometer

ST500 | Factory Settings – How do I reset the inverter?

ST500 | Change display (rpm)