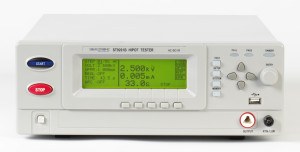

High voltage test

High-voltage tests are performed for appliances with protection classes I (with a PE protective conductor) and II (without a PE protective conductor). In the process they determine whether the insulation of the current-carrying conductor and the safe distance from the device casing meet the specifications.

A high voltage test is considered “good” when no current flows. In an AC high-voltage test on a device under test with capacitive characteristics, however, a weak current will flow. Therefore, most test devices have adjustable settings. As a guide for the voltage during a high-voltage test, double the usual voltage of the DUT you are testing and add 1,000 V. For a 230-volt device, that is: 1000 V + 2 x 230 V = 1460 V (1500 V).

is considered “good” when no current flows. In an AC high-voltage test on a device under test with capacitive characteristics, however, a weak current will flow. Therefore, most test devices have adjustable settings. As a guide for the voltage during a high-voltage test, double the usual voltage of the DUT you are testing and add 1,000 V. For a 230-volt device, that is: 1000 V + 2 x 230 V = 1460 V (1500 V).

A distinction is drawn between AC and DC high-voltage tests. The VDE (Association for Electrical, Electronic & Information Technologies) recommends the DC high-voltage test for production facilities. It is less risky and cannot damage the human heart. For job safety, the requirements of the professional association apply (to EN 50191). Additional workplace security is not needed during voltage testing with AC up to 3 mA or DC up to 12 mA. The DC high-voltage test, thus, has the added advantage that no extra precautions are required for tests of 12 mA or less.

Safety at work:

a) High-voltage tests with currents : |> 3 mA / AC or |> 12 mA / DC

– Special high-voltage test room, or

– Sealed-off area, warning sign, warning lights, test probes / test cage / two-handed operation.

b) High voltage tests with currents: class I

– No safety precautions, or

– Provisional precautions against “secondary accidents”, e.g. twitches and lurches after an electrical shock.

High-voltage tests on specimens with suppression capacitors and Y-capacitors can be done with either AC or DC. The charge current measurement, as part of the DC high-voltage test, can also provide information about the built-in noise suppression capacitor.

« Back